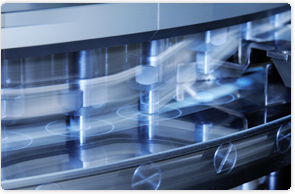

OSDrC® technology includes several technologies, such as variable double punches, that go beyond the parameters of current tableting machines. The very latest technologies developed through a range of simulations have been harnessed, creating the ability to manufacture these innovative tablet configurations at a rate of 100,000 per hour, while avoiding such problems as misaligned cores, mass variability, and cross-contamination.

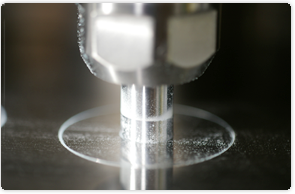

OSDrC® technology is an innovative new pharmaceutical manufacturing technology that produces precise tablets of nearly any shape using a variable double-punch configuration. This rotary tableting machine has 54 double punches and three feeders. Because the tablets are produced in a single step while the punches make one rotation on a turntable, there is no longer any need for a separate stage to deliver the core. Because the core is held in place by the lower outer punch until immediately before the final compression, misalignment does not occur.

The types of tablet configurations that can be manufactured with OSDrC® are unlimited, depending only on the double-punch variations. OSDRrC technology lets formulators and process engineers freely control the appearance of the tablet and shape of the core, as well as giving them the ability to select the thickness of the coating and precisely control the core's position. This paves the way for completely new types of drug products, such as dividable cored tablets, that were not possible with existing technology.

An innovative cam design is the key to the movement of the double punch system. This cam function allows complex and independent punch movements while maintaining comparable or better productivity than conventional tableting machines.

The OSDrC® rotary tableting machine incorporates specifically designed components to prevent cross-contamination of powders. With design elements to collect surface contamination, eliminate powder residue, and recycle excess powder, tableting efficiency of 95% can be achieved. This makes a significant contribution to cost savings.

The OSDrC® rotary tableting machine also comes equipped with several highly advanced functions conforming to Good Manufacturing Practice (GMP) standards, including a pressure monitor for each layer, automatic sampling, and an automatic exclusion mechanism.